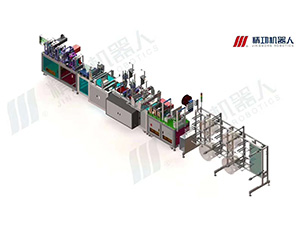

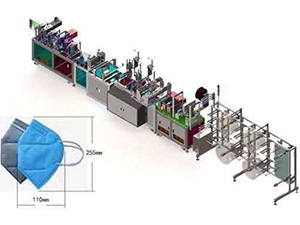

Fully Automatic Folding All-in-One Mask Production Line

Equipment Introduction

This machine is used for automatic forming of folding masks, the whole process including: raw material roll unwinding, roller driving, feeding nose clip, welding and wrapping nose clip, (pneumatic valve hole optional), (printing optional), welding earloop 1, welding earloop 2, folding, edge welding, cutting, finished product output, remaining material output and etc., then conveyed out. The entire process is fully automated. The production line has advantages such as stable performance, high output capacity, low defect rate, and easy operation.

Raw Material Recommendation

Cloth(meltblown nonwoven, PP nonwoven)

Qty.:2~4rolls OD*ID:600mm*76mm

Cloth width OD*ID:280(300)(max. width 300)

Nose clip OD*ID:1roll 400mm*76mm (width 3mm,thickness 0.35mm aluminum strip〉

Earloop :2rolls OD*ID:width 3mm

Equipment Parameters

| Dimension | 8000mm(L) X1400mm(W) X1600mm(H) |

| Color | 1C International standard warm grey 1C |

| Weight | ≤5000kg, ground weight capacity ≤500kg/m2 |

| Working power | equipment 220VAC±5%; 50HZ;rated power 17KW |

| Working air pressure | Compressed air pressure 0.5-0.8MPa; compressed air flux 300L/min(stable flux guaranteed; oil and water have to be filtered) |

| Production efficiency | 1800-2500PCS/H(based on 20 hours each day, daily capacity about 36,000-50,000 pieces) |

| Qualification ratio | 99%(excluding unqualified incoming materials, improper operation by employees) |

| Equip failure ratio | ≤2%(equipment failure itself) |

| Operating environment | Temperature 10一35℃; humidity: 5-35%HR No flammable, corrosive gas, no dust (cleanliness no less than 100,000 grade) |

Curving Punching Forming Machine

Curving Punching Forming Machine Downspout Forming Machine

Downspout Forming Machine EPS Sandwich Panel Machine

EPS Sandwich Panel Machine Film Cutting Machine

Film Cutting Machine Guardrail Forming Machine

Guardrail Forming Machine