Robotic Polishing System

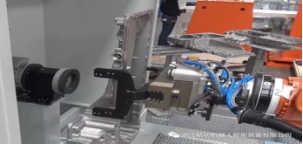

The robotic polishing system is extensively used for surface treatment (grinding, polishing, deburring and mercerizing). This robotic die polishing system mainly focuses on metal polishing and deburring, as well as non-metal deburring and milling. It is primarily classified into two modes: robot with tool head and robot grasping workpiece that needs to be handled on the operation machine.

Advantages

Our robotic polishing system adopts high-accuracy robots with high speed electric spindle and automatic blade change to realize valve milling, grinding and polishing. Laser scanner is used to automatically correct the working directions for workpieces.

Application

The robotic die polishing system can debur, mill, drill and handle workpieces within one station, including special-shaped parts like elongated metal workpieces.

Door Frame Roll Forming Machine

Door Frame Roll Forming Machine Guard Rail Roll Forming Machine

Guard Rail Roll Forming Machine Roller Shutter Door Forming Machine

Roller Shutter Door Forming Machine C/U Channel Roll Forming Machine

C/U Channel Roll Forming Machine