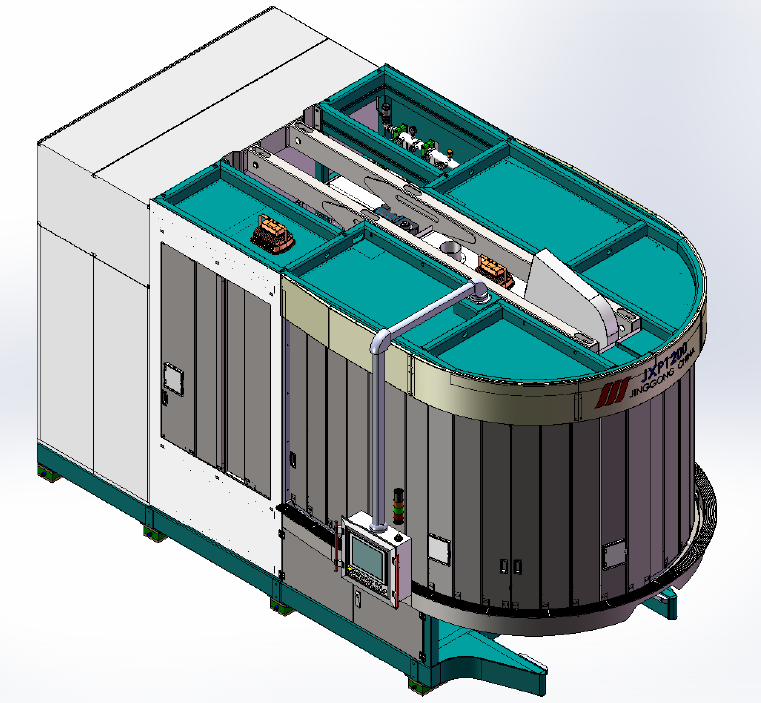

JXP1200 DW Polysilicon Ingot Squaring Machine

Main Parameter

Voltage: 415V AC

Frequency: 50Hz

Phase: 3 phase

General power: 80kW

Equipment full-load current: 160A

Electric protection grade: IP54

Standard ingot size: 1190 × 1190 × 500mm

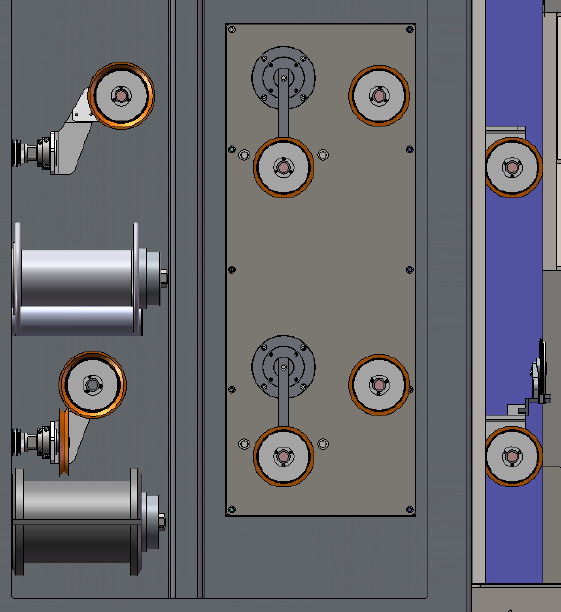

Guiding wheel quantity: 4 groups

Max. diameter of guiding wheel: ⌀300mm

Height gap between up and down wire layer: 50mm

Max. wire speed: 13m/s

Acceleration: 3m/s2

Wire tension: 10-150N

Wire releasing wheel: TA100

Wire releasing driving motor: 2 × 17.5kW

Shearing head feeding travel: 650mm

Shearing head feeding speed: ≥1.8mm/min

Feeding motor power: 0.82kW

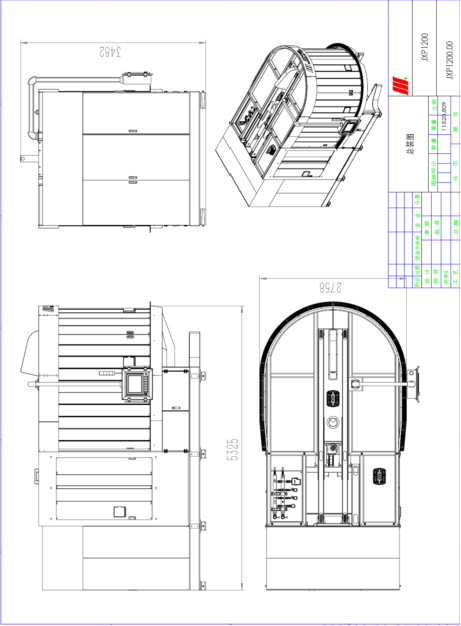

Equipment size (L× W × H): 5350 × 2600 × 3150mm

Equipment weight: about 16T

Final Acceptance Criteria

| Wire returning rate | ≥98.7% (≤1.6km per ingot) |

| Feeding speed | 1.8mm/min |

| Flatness | ≤0.6mm |

| Perpendicularity | 90°±0.2° |

| Wire breaking rate | ≤3% |

| Squaring yield | ≥99.5% |

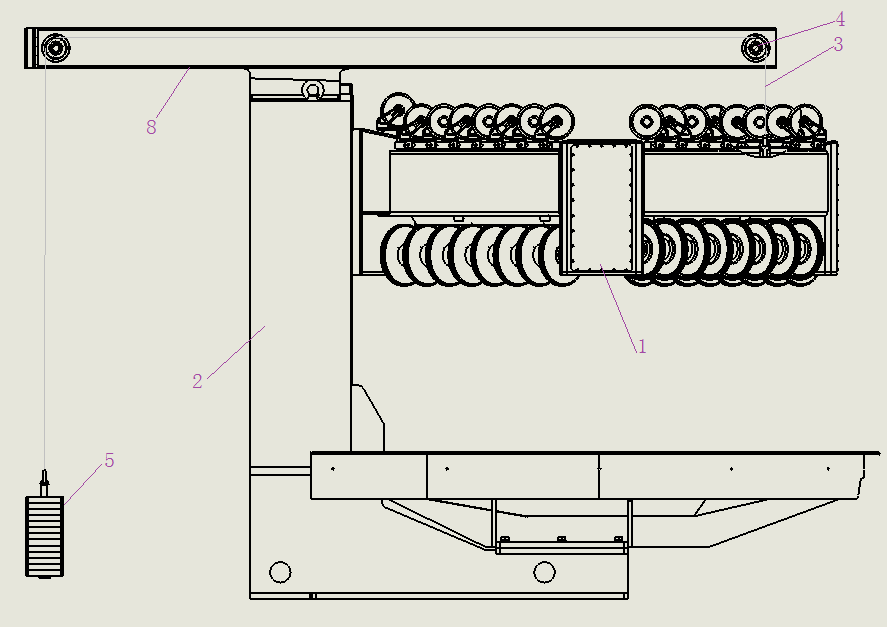

1. Frame.

It is the support part of the polysilicon ingot squaring machine, consisting of base part and upper parts. The base part is assembled to support the whole machine. The upper part is made of stainless steel to avoid corrosion from mortar.

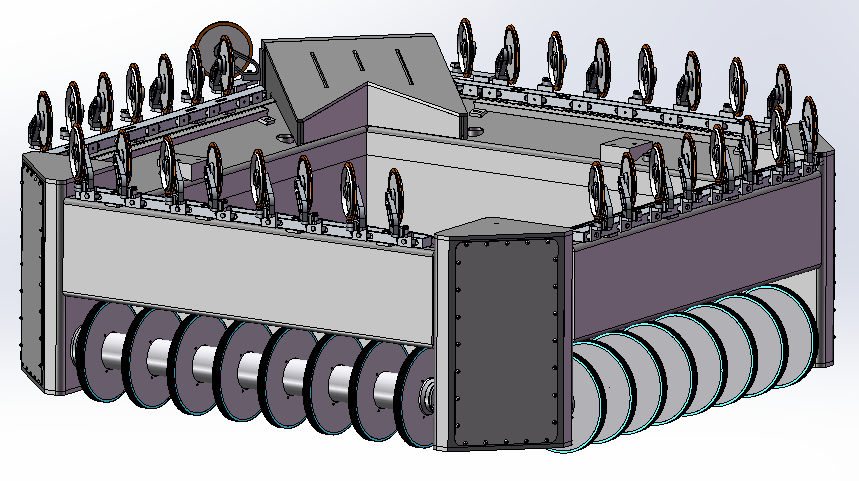

2. Squaring room

The squaring room of this polysilicon ingot squaring equipment mainly consists of vertical frame, small guiding wheel, squaring head, mortar pool, ingot support, etc. As the mortar is corrosive, most parts in the squaring room are made of stainless steel. Moreover, the movement mechanism is plated with sealing glue for corrosion resistance. The stainless steel door must be closed while working. The squaring head is the key part of the machine, made of stainless steel.

3. Weight balance system.

The weight balance system of the polysilicon ingot squaring machine is used to balance the cutting head weight and protect the guiding rail. Moreover, it can help to reduce deformation of cutting head and increase the cutting accuracy of ingot.

4. Control system.

The control system of the polysilicon ingot squaring equipment adopts Siemens SIMOTION motion controller and advanced Siemens servo motor. Other low-voltage elements adopt ABB brand to ensure the performance and accuracy of this polysilicon ingot squaring machine. Siemens touch screen or Advantech touch screen is equipped for ease of operation.

Below is the HMI interface during auto running:

Main Part Supplier

| No. | Item | Model | Supplier |

| 1 | Lifting guiderail | M-V8050 | INA |

| 2 | Combination bearing | ZARF3080TVA | INA |

| 3 | Roller bearing | NU208E | SKF |

| 4 | Angle contact bearing | 7208B | SKF |

| 5 | Servo motor | 1FK7064-5WF70-1DA0 | Siemens |

| 6 | Ball screw assembly | JXP1000-02, 02-306 | HIWIN |

| 7 | Roller bearing | NU313E | SKF |

| 8 | Pneumatic ratio valve | ITV2050-312S-X26 | SKF |

| 9 | Low friction cylinder | MQMLC20_100D | SMC |

| 10 | Other pneumatic element | SMC | |

| 11 | Mass flow meter | R200S128NWEAMZZZ | Emerson |

| 12 | Main controller | Siemens | |

| 13 | Servo system | Siemens | |

| 14 | Low voltage elements | ABB | |

| 15 | Water flow sensor | IFM | |

| 16 | Water cooling AC | ALLURN |

nstallation and Production Requirements on Site

Before installation, the Buyer shall prepare the following items:

Factory building and foundation: width: ≥16m, height: ≥6m, foundation made of C25 concrete, with thickness of 200mm and flat ground.

Power requirement (depend on Buyer’s condition):

Capacity: 80kW

Voltage: 3P/415±10%V AC, 50Hz.

Environment humidity: <85% (non-condensing), 5 ~ 30°C

Cooling water:

Water quality: in compliance with GB11446.1-1997EW-IV standard

Flux: 6m3/h

Water pressure: 0.35-0.45Mpa

Pressure difference: 0.2Mpa

Temperature: 20-22°C

Compressed air: dry and clean compressed air in compliance with DIN ISO8573-1,3.

Air pressure: 0.4-0.6Mpa. Air consumption: 60m3/h.

Lifting equipment: capacity more than 16T.

Spare Part List

| Item | Quantity | Remark |

| Roll sleeve | 3 sets | JXQ600.04.07-306 |

| Small pulley device | 2 sets | JXP1000A.04.10-001 |

| Big PU pulley | 30 sets | JXP1000A.04.09-301 |

| Small PU pulley | 150 sets | JXP1000A.04.10-301 |

| Wire guiding wheel | 1 set | JXP1200.03.05-001 |

| Ball bearing | 4 sets | 6202-2RZ |

| Ribbed belt | 1 set | 920-8M40 |

| Ribbed belt | 1 set | 960-8M40 |

| Cutting piece | 1 set | |

| Ingot support base | 1 set | |

| Air tube joint | 2pcs | |

| Air tube | 5m | |

| Tray | 1 pc | |

| Maintenance tooling | 1 set | |

| Diamond wire | 1 coil |

Door Frame Roll Forming Machine

Door Frame Roll Forming Machine Guard Rail Roll Forming Machine

Guard Rail Roll Forming Machine Roller Shutter Door Forming Machine

Roller Shutter Door Forming Machine C/U Channel Roll Forming Machine

C/U Channel Roll Forming Machine