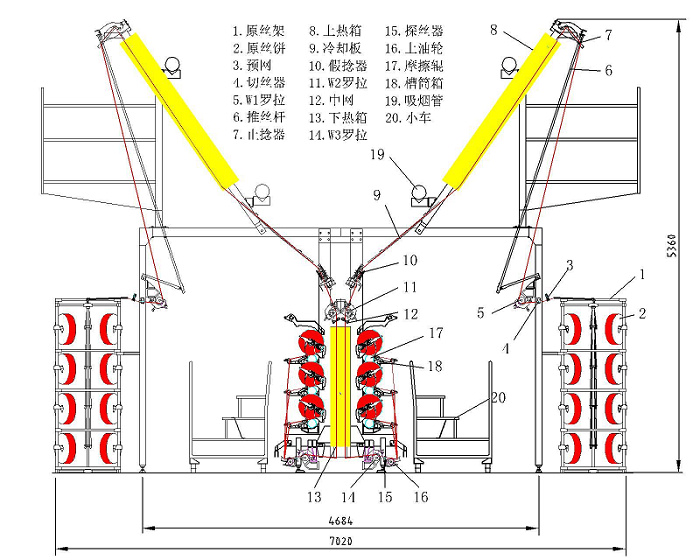

JGT1000 series V machine

Introduction

This machine mainly use is the POY yarn ( polyester silk) is through stretching and false twisting deformation, processed into low elastic or high elastic deformation of the false twisting silk ( DTY stretch yarn), the equipment can be option to add the network components, so it can undertake network yarn processing.

1、TECHNICAL PARAMETERS

|

spindles |

240spindles |

264spindles |

288spindles |

|

|

sections |

10 |

11 |

12 |

|

|

spindles pitch |

110mm |

|||

|

Highest mechanical speed |

1000m/min |

|||

|

raw material and fibre number |

55-333dtex(50- 300Denier)/polyester 55-333dtex(50- 300Denier) |

|||

|

section size |

1440mm |

|||

|

false twist way |

folding disc 8type false twister, friction false twisting |

|||

|

the highest speed of false twist device |

18000 r/min |

|||

|

false twist direction |

S,Z |

|||

|

The first heat box (distortion) |

biphenyl gas phase heating/2500mm |

|||

|

The second heat box ( figuration) |

biphenyl gas phase heating/1460mm |

|||

|

figuration heat box temperature range |

160-250℃ |

|||

|

figuration heat box temperature range |

160-250℃(low temperature biphenyl as 100-180℃) |

|||

|

cooling mode and length |

cooling plate cooling/1100mm |

|||

|

friction roller diameter |

Φ100mm |

|||

|

roller diameter |

Φ75mm |

|||

|

oiling roller diameter |

Φ75mm |

|||

|

largest original yarn size |

Φ435×250mm |

|||

|

maximum take-up size |

Φ250×250mm |

|||

|

standard take-up capacity weight |

5kg |

|||

|

take-up paper pipe specifications |

Φ69×Φ57×290mm |

|||

|

installed power category |

drive |

93.5.5 kw |

107.5kw |

110.5kw |

|

up heat box |

68 kw |

74.8kw |

81.6kw |

|

|

below heat box |

24 kw |

26.4kw |

28.8kw |

|

|

assist power |

6kw |

|||

|

total power |

191.5kw |

214.7kw |

226.9kw |

|

|

dimensions (with fixed original wire frame) |

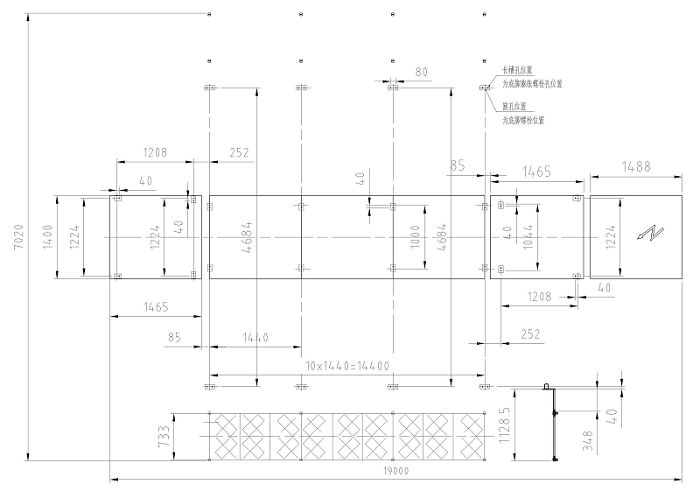

19000×7020×5360 mm |

20440×7020×5360 mm |

21880×7020×5360 mm |

|

2、Equipment performance and characteristics of main components

The new structure design and control mode, the single roller , single motor drive directly, canceled synchronous belt, reduce the transmission chain length, improve the transmission efficiency, on both sides of the machinecan be relatively independent operation, on a left process can be adjusted respectively set, in the same equipment, processing can be two different original silk and yarn, and improve the equipment utilization, realize the multi-usage.

The machine is equipped with two ways of heat box, the first heat box (deformation heat box ) and the second hot box (figuration heat box) is using biphenyl gas phase heating, closed structure, it increase the internal heat preservation methods, use PLC control heating and temperature control, temperature control precision is ±10C, effectively ensure the yarn quality, it is more advantageous to dyeing and keeping more uniformity.

PLC control system, the machine through man and machine communication, to realizes process adjustment. The touch screen and operation made the process set simply and easily, so it is easy to understand, using the network, Interface can according to the needs of the users, people can do more machine networking management.

Use the high quality of electrical components, to ensure that equipment in use process operation more reliable, more stable.

The fold type disc VIII false twist device, import ceramic plate and blade export plate installation, configuration optional scope of the1-4-1-1-4-1.

W1/W2/W3 roller adopts the roller type structure

,aluminum alloy roller frame, uniform pressure, the W2 with yarn roller.

High speed winding shaping system, forming good, easy to unwinding, the biggest capacity can be processing to 6kg

3、DIMENSION DRAWING

Slitting Line

Slitting Line Cut To Length Line

Cut To Length Line Simple Cut to Length Line

Simple Cut to Length Line Racking Roll Forming Machine

Racking Roll Forming Machine