Home » Gallery

Product

Fully Automatic Folding All-in-One Mask Production Line

Fully Automatic Medical Mask Machine

Building Materials

Construction Materials Machinery

Steel Structure Machine

Cold Roll Forming Machine

Racking Roll Forming Machine

Cable Tray Roll Forming Machine

C/U Channel Roll Forming Machine

Door Frame Roll Forming Machine

Guard Rail Roll Forming Machine

Roller Shutter Door Forming Machine

Roofing Sheet Roll Forming Machine

Wall Panel Roll Forming Machine

Sandwich Panel Roll Forming Machine

Slitting Line/Cut To Length Line

Slitting Line

Cut To Length Line

Simple Slitting Line

Simple Cut to Length Line

Shot Blasting Machine

HPG H-beam Shot Blasting Machine

JPG Steel Plate Shot Blasting Machine

JPG Steel Pre-Treating Shot Blasting Machine

Metal Coil Sheet/Metal Corrugated Panel Product

Roofing Panel Sheet

Wall Panel Sheet

Steel Decking Panel Sheet

C/Z Purline

EPS/PU Sandwich Panel

Coil Sheet

Textile Equipment

JGT1000 series V machine

HIGH SPEED SPANDEX COVERING MACHINE

JGR231 Type Rotor Spinning Machine

HKV151 Type Fancy Twister

HKV101B Type Winder

Data Cabinets Industry

JMDKG-09B Parallel Cabinet

JMDKG-09D Free Standing Electrical Enclosure

JMFG-05T

JMFG-09B Top-Level Server Cabinet

Cold Channel Closed System

Photovoltaics

JXQ800 Diamond Wire Slicing System

JJL1200A Polysilicon Ingot Furnace

JXP1200 DW Polysilicon Ingot Squaring Machine

Robot Intelligent

Laser Welding System

3D Robotic Laser Cutting System

Robotic Arc Welding System

Robotic Polishing System

Automated Conveyor Line

Automated Logistics System

Special Equipement

Precision Processing

Hot Products

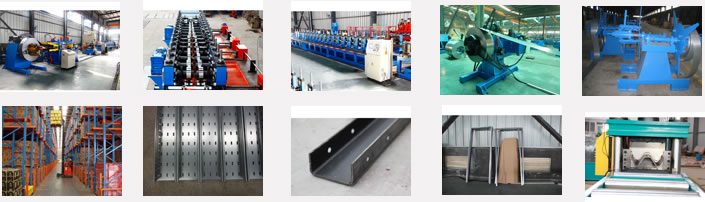

- Racking Roll Forming MachineRacking roll forming production line adopts servo controlled material feeding technology for complex punching to guarantee precision. This storage rack roll forming equipment also adopts track cutting technology to ensure the machine capacity and gear box transmission and ensure the machine’s rigidity and working strength. Racking roll forming production line is also known as shelf roll forming equipment, shelving rack roll forming machine

- Cable Tray Roll Forming MachineCable tray roll forming machine (also called cable ladder roll forming machine) is capable of making different sizes of cable trays through replacing punching moulds. The cable trays produced by this roll forming production line are extensively used in factories and other buildings because of their accurate robustness. It consists of decoiler (uncoiler), leveling machine (flattener), servo feeding device

- C/U Channel Roll Forming MachineLanteky Science possesses more than 15 years’ production experience of roll forming equipment. C/U channel roll forming equipment is well known for its strong and durable design. This roll forming production line is capable of rolling steel sheets up to 6 mm. It can be widely used in the large and medium-size enterprise civil construction, such as plant, warehouse, locomotive shed

- Door Frame Roll Forming MachineDoor frame roll forming production line is designed to roll the cold rolled galvanized sheets with the thickness from 0.4 mm to 1.5 mm. This cold roll forming equipment consists of hydraulic uncoiler, leveler, servo feeder, punching device, roll forming unit, fly shearing device, run-out table, hydraulic station and electric control cabinet. The hydraulic station of Lanteky Science door frame roll forming machine adopts accumulator and PLC controller