Laser Welding System

Description

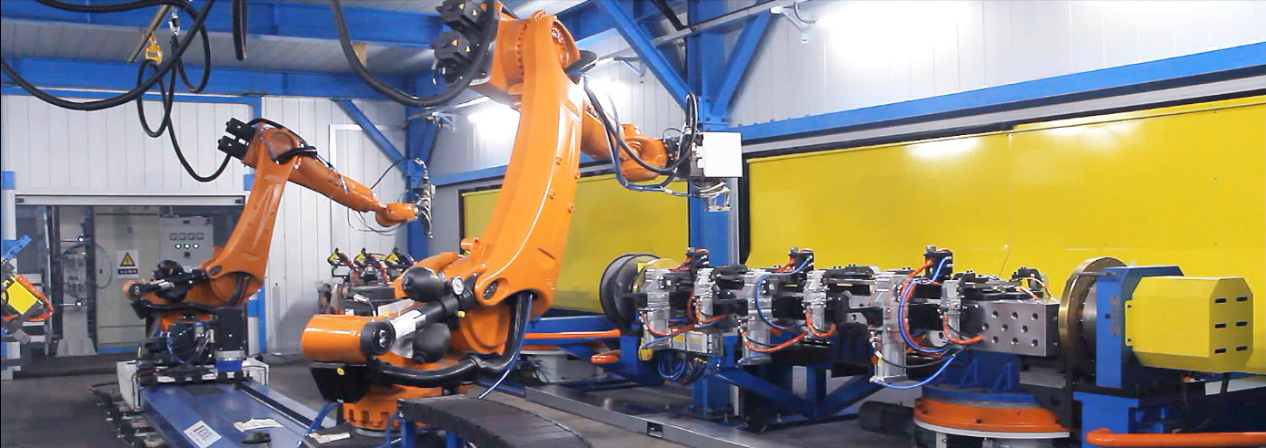

Industrial laser welding usually adopts deep penetration fusion welding of medium and high power laser. It uses robot with laser welding head or laser welding machine with CNC shaft and laser welding head to weld the welding parts. The welding parts need to be clamped with precise tool. Laser welding has the advantages of high welding efficiency and quality, and small welding heat-affected area. Laser welding system has been extensively used in automobile industry, and increasingly applied by industries like thin metal and stainless part welding, gear welding, etc.

- Features

- 3-5 times faster than MIG/MAG welding.

- Heat-affected zone of welding parts is small, reducing deformation.

- High depth-to-width ratio (max. 10:1).

- High-quality welding seam, with strength higher than the parent metal.

- No need of surface treatment.

- Quality can be controlled.

Application

Robotic laser welding line is widely used in metal sheet processing, automobile manufacturing (car chassis, seat frame, guide rail, muffler, hydraulic torque converter, etc.), kitchen equipment, electronic engineering, medical treatment, mould manufacturing industry, etc.

Door Frame Roll Forming Machine

Door Frame Roll Forming Machine Guard Rail Roll Forming Machine

Guard Rail Roll Forming Machine Roller Shutter Door Forming Machine

Roller Shutter Door Forming Machine C/U Channel Roll Forming Machine

C/U Channel Roll Forming Machine