- Laser Welding SystemIndustrial laser welding usually adopts deep penetration fusion welding of medium and high power laser. It uses robot with laser welding head or laser welding machine with CNC shaft and laser welding head to weld the welding parts. The welding parts need to be clamped with precise tool. Laser welding has the advantages of high welding efficiency and quality, and small welding heat-affected area.

- 3D Robotic Laser Cutting System3D robotic laser cutting system is an advanced laser cutting equipment that uses special optical fiber laser cutting head, high-precision capacitance tracking system, fiber laser and industrial robot system to flexibly cut the metal sheet into different thicknesses from multi angles and positions.

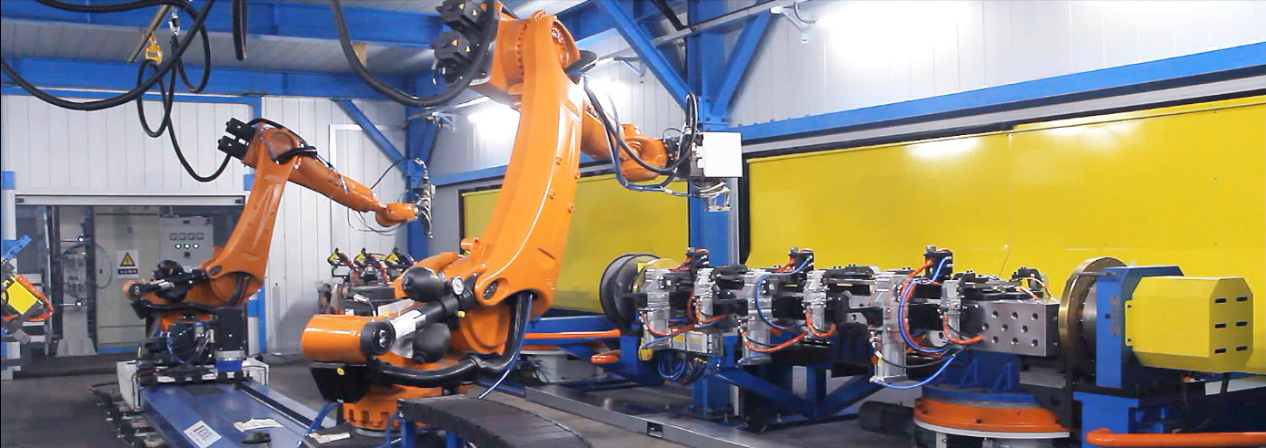

- Robotic Arc Welding SystemThe robotic arc welding system covers almost all areas of welding production, including automotive vehicles and spare parts, engineering machinery, ships, steel structure, high speed trains, pressure containers, etc. Welding materials include low-carbon steel, stainless steel, aluminum, etc. with thickness ranging from not more than one millimeter up to dozens of millimeters.

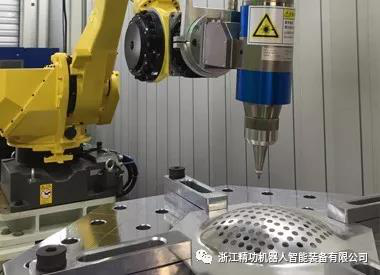

- Robotic Polishing SystemThe robotic polishing system is extensively used for surface treatment (grinding, polishing, deburring and mercerizing). This robotic die polishing system mainly focuses on metal polishing and deburring, as well as non-metal deburring and milling. It is primarily classified into two modes: robot with tool head and robot grasping workpiece that needs to be handled on the operation machine.

- Automated Conveyor LineThis automated conveyor line can carry out automatic wiring, calibration and image recognition.

- Automated Logistics System This automated logistics system covers automated multi-layered storehouse system, stacker, AGV, stacking/unstacking robot, RGV, conveyor system, high speed sorting system, electric control system and computer software system, etc. The robotic logistic system is extensively applied to automatic three-dimension warehouse, storage center, distribution center,

Robot Intelligent

Laser Welding System

Industrial laser welding usually adopts deep penetration fusion welding of medium and high power laser. It uses robot with laser welding head or laser welding machine with CNC shaft and laser welding head to weld the welding parts. Laser welding system has been extensively used in automobile industry, and increasingly applied by industries like thin metal and stainless part welding, gear welding, etc.

3D Robotic Laser Cutting System

3D robotic laser cutting system is an advanced laser cutting equipment that uses special optical fiber laser cutting head, high-precision capacitance tracking system, fiber laser and industrial robot system to flexibly cut the metal sheet into different thicknesses from multi angles and positions.

Robotic Arc Welding System

The robotic arc welding system covers almost all areas of welding production, including automotive vehicles and spare parts, engineering machinery, ships, steel structure, high speed trains, pressure containers, etc.

Robotic Polishing System

The robotic polishing system is extensively used for surface treatment (grinding, polishing, deburring and mercerizing). This robotic die polishing system mainly focuses on metal polishing and deburring, as well as non-metal deburring and milling.

Automated Logistics System

This automated logistics system covers automated multi-layered storehouse system, stacker, AGV, stacking/unstacking robot, RGV, conveyor system, high speed sorting system, electric control system and computer software system, etc. The robotic logistic system is extensively applied to automatic three-dimension warehouse, storage center, distribution center, and various conveying lines, testing lines and automobile assembly lines of AGV.

Door Frame Roll Forming Machine

Door Frame Roll Forming Machine Guard Rail Roll Forming Machine

Guard Rail Roll Forming Machine Roller Shutter Door Forming Machine

Roller Shutter Door Forming Machine C/U Channel Roll Forming Machine

C/U Channel Roll Forming Machine